Jacquard - turning possibly average into exceptional fabrics

What is a Jacquard fabric?

Jacquard fabric is a type of cloth featuring an intricate pattern woven into the warp on a special mechanical loom, rather than printed on the surface.

How did it get its name?

It was a French weaver Joseph-Marie Jacquard who invented this technology in 1804, so the jacquard fabric was named after him.

What purpose do Jacquards serve?

These fabrics are available in a variety of compositions and weights and serve various purposes. Lightweight jacquard fabrics are often picked for spring and summer apparel, whereas the heavier variety is preferred during colder seasons.

Can you tell something about the Jacquard designs?

Jacquards come both in tone-on-tone and contrast designs, and a choice of patterns is unlimited. It could be from classic stripes and polka dots to fancy botanicals, florals and even conversational themes. Unlike prints which are applied to the fabric after it is woven, jacquard patterns are created together with the cloth. The beauty of the jacquard loom is in its ability to interlace hundreds of warp threads to create unique designs.

How do you recognize a jacquard created design?

A jacquard fabric is all about the pattern, which looks that unique due to the way it is applied. Very often, if you look at the back of the cloth, long floats can be found; these are threads used to produce the pattern, and it tells you straight away that you are dealing with jacquard.

Are all jacquards woven?

Though most jacquards are woven, you also have knitted options. Jacquard knit is either a single or double knit fabric made with any yarn. Compared to single cloth, double knit has no floats on the back and is reversible.

Is there any particular fibre for the making of a jacquard?

No. Since jacquard is a type of weave rather than a type of material, it can be made with a vast range of fibers.

Kindly tell about the effect of jacquard on different fibres.

| Fiber | What to Expect | Suitable For |

| Cotton | Soft, breathable, opaque, worn all year round | Shirts, tops, blouses, dresses, pants, skirts, jackets, sweatshirts |

| Silk | Smooth, glossy or dull, thin, semi-sheer or opaque,

worn in spring/summer and on special occasions |

Blouses, tops, dresses, skirts, scarves, lingerie, ties, lining |

| Wool | Soft, cozy, opaque, perfect for fall/winter | Dresses, jackets, skirts, pants, coats, blazers, sweatshirts, cardigans |

| Linen | Soft, breathable, opaque, worn in spring/summer | Dresses, shirts, skirts, tops, pants, wraps |

| Blend | From soft to slight wiry, various degrees of transparency, most are for four-season wear | Shirts, tops, blouses, dresses, pants, skirts, jackets, sweatshirts, coats |

What is the range of Jacquard fabrics?

Jacquard fabrics are widely used for clothing, ties, slings, ribbons, as well as for home décor: upholstery, draperies, curtains, table and bed linen, etc. In terms of design, there is no limit to imagination. You can find anything from florals, paisley, stripes and polka dots to very large, detailed, intricate patterns that can tell a whole story.

What is the effect of blending Jacquard fabrics with elastic fibres?

Any jacquard becomes stretchy when mixed with elastic fibers – spandex, lycra or elastane. Stretch jacquard has the same usage, but is especially suitable for body-hugging and fitted styles.

Is there a variety to jacquard fabrics?

Yes. You also have double-faced or double-sided types of this fabric. These are woven with two face sides, usually in contrasting colors, and are reversible. The good thing about such designs is that you are free to use both sides for sewing.

E.g. you buy jacquard fabric by the yard and use one side for a jacket, and the other for a skirt. Or, you may sew your project using one side, and save the other for contrast details like cuffs, pockets, lapels, etc.

What are the Jacquard fabric properties that give them an advantage?

The advantages of jacquard materials depend a lot on composition. Still, there are some characteristics they all share in common. Most jacquard weave materials have floats on the back side. Plus, they are:

durable and stable,

strong and resilient,

wear- and wrinkle-resistant,

pleasant to the touch,

filled with decorative aesthetics.

Why are jacquard fabrics viewed differently?

There are two reasons why jacquards stand apart from the rest of woven fabrics.

- First - the complexity of the design. Before the invention of the jacquard loom, detailed patterns were made by hand and involved a lot of labor and time. Nowadays, highly detailed motifs are woven automatically in a much shorter time. The secret is in controlling warp yarns. The jacquard loom creates a pattern by selecting and lifting warp yarns.

- Second, the number of colors used. Modern technologies make it possible to produce sophisticated designs with a large or small repeat in the desired color range. You can weave anything you like using just one color or dozens of them: geometry, flora and fauna, abstract shapes, complex figures, etc.

Jacquard fabrics tend to have a raised surface, though sometimes the pattern is so delicate you can barely feel it under your fingers. Silk jacquard is the perfect illustration.

What are the different kinds of fabrics woven on the jacquard loom?

There are several kinds of fabrics produced on a jacquard loom.

| Type | Description | Common Use in Apparel |

| Brocade | A patterned raised cloth woven with multicolored threads. Usually heavy and rich, it is worn mainly on special occasions. Non-reversible, it can also contain metallic threads. | Evening wear such as dresses and skirts, fancy jackets and coats |

| Damask | A reversible patterned fabric woven in cotton, silk, linen, viscose, etc. Smooth and lustrous, it is finer than brocade. Damasks can be tone-on-tone or multicolored, which means that the colors of the background and the pattern reverse from front to back. | Dresses, skirts, blouses and tops, shirts, coats, ties |

| Matelasse | A fabric with a raised quilted effect, usually woven in solid colors. It is made with silk, cotton, wool, viscose and comes in all sorts of designs, from graphic to floral motifs. Matelasse can also be hand-stitched. | Outerwear jackets and coats, dresses and skirts, handbags |

| Cloque | A fabric with a jacquard weave featuring a puckered or blistered effect. Often comes in silk, wool and cotton blends. | Dresses, skirts, blouses, jackets |

| Tapestry | A fabric with a jacquard weave that imitates tapestries. Thicker and heavier than damask or brocade, sometimes it can reverse the colors like damask. | Outerwear jackets and coats |

| Brocatelle | A tightly woven type of jacquard similar to damask, but with a raised, embossed pattern. Non-reversible, it often comes in a woven mix of silk, cotton, rayon or viscose. | Haute couture wear |

Is silk Jacquard something special?

Yes it is. Silk jacquard has been conquering the fashion world season after season. Whether made of pure silk or silk blends, this exclusive fabric has a lot to offer. Unlike printed silk, its pattern is the result of elaborate weaving and is often slightly textured to the touch.

Are all silk fabrics made on a jacquard loom, considered to be jacquard?

Yes. All silk fabrics made on a jacquard loom are considered Jacquard. Some of the examples are:

- silk organza

- silk taffeta

- silk crepe de chine

- silk chiffon

- silk satin

Could you give some ideas on the uses of silk jacquard fabric?

Every season leading fashion houses come up with exquisite designs that serve as inspiration for sewing addicts: jacquard dresses and gowns, intricately patterned skirts and trousers, fancy blazers and accessories. Suggestions to look stunning are given below:

-

- a halter-neck sheath dress,

- a form-fitting jacket with a full skirt,

- a pantsuit teamed with a sheer blouse,

- a wrap dress with a ¾ sleeve,

- a pair of straight trousers with a tone-on-tone design;

- a silk duster coat.

What can you tell about the cotton jacquard fabric?

Cotton jacquard is another type of natural jacquard options that bring the best properties of cotton fabrics to a wide range of fashion garments and accessories. You ask what is special about this fabric? Well,

-

-

- Cotton jacquard doesn’t wrinkle,

- It makes amazing drape,

- It is very durable.

- If made of finest Egyptian cotton, this fabric is typically lightweight and has a soft finish, which makes it a perfect match for dresses, skirts, jackets and trousers.

-

What is special about the cotton Jacquard?

Like any cotton fabric the cotton jacquard is hygroscopic, hypoallergenic and environmentally friendly. However more than that, the cotton jacquard is mainly about its double-sided pattern that can be multi-coloured or two-tone. It is convex on one side and slightly concave on the other. The colours in such pattern are reflected mirror-like — if there’re dark colours on one side, then on the other side they are bright. The fabric is easy in care: it is machine-washable in 30°C and can be ironed on the inside out.

How does one care for a Jacquard fabric?

Since jacquard is a type of weave and can be made of any fibers, care instructions depend a lot on the fabric you hold in hands. Some jacquards are ok with washing, while some of them prefer dry-cleaning. Here are a couple of tips you might find useful:

-

-

- If the jacquard fabric is too delicate or, quite the opposite, very rich and ornate, with metallic yarn, sequins or beadwork, dry-cleaning is the best strategy to keep it safe.

- Sturdy jacquard fabrics can be hand and machine washed at 30 °С. Avoid using bleaching agents. Do not wring this fabric. Instead, let it dry on a hanger or lay it flat on a table, away from direct sunlight.

- If you choose to press a jacquard fabric, it is recommended to do it from the wrong side so as not to damage the pattern.

-

What are popular designs and patterns for Jacquard fabrics?

-

-

- Jacquard is beautiful on many levels. It gives you free rein to explore your designer skills since you can choose any weight, any finish and any composition.

- If you are looking for something lightweight silk or cotton jacquard fabrics suit for the purpose and the look.

- But if you want something more substantial then a wool or blend jacquard is the answer. Whether you are working on some sort of special event wear or a low-key outfit, jacquard weave has got the potential to cater for every need.

- The hottest trends in 2019 have been stripes, checks, and florals. While printed fabrics are all the rage, jacquards are a perfect alternative for those who want to try something different. Fashion designers like to clash various textures and don’t mind matching the unmatchable.

-

Do Jacquard fabrics serve any other purpose?

An important jacquard application field is home décor. The peculiarities of its weave make it lustrous and durable, thus much important for curtains, drapery, upholstery, headboards, carpet bags, etc.

The most popular applications of this fabric are curtains, explained by the following reasons:

-

-

-

-

- impressive weight about 250 g/m² that protects your room from sunrays and provides a cosy twilight even when the Sun is at its highest point;

- wear resistance — jacquard curtains neither fade nor stretch out. This material is also well-washable. Just prevent it from mechanical damages;

- easy-to-care — jacquard curtains don't absorb water, any contaminations can be eliminated with a wet cloth, while heavy stains can be washed in a washing machine;

- luxury appearance — historically, jacquard curtains have always been used for banquette halls, the living rooms of expensive restaurants and hotels. Even the curtains of a lower price segment can make wonders in the decoration of any premise.

-

-

-

What is the Jacquard loom?

The Jacquard machine is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. The resulting ensemble of the loom and Jacquard machine is then called a Jacquard loom. Since it was invented by Joseph Marie Jacquard in 1804 hence the name Jacquard.

Tell us something more about it.

-

- Based upon earlier inventions by the Frenchmen Basile Bouchon(1725), Jean Baptiste Falcon (1728) and Jacques Vaucanson(1740), Joseph Marie Jacquard brought about modifications and the form as used across the world today.

- Initially the machine was controlled by a “chain of cards”; a number of punched cards laced together into a continuous sequence. Multiple rows of holes were punched on each card, with one complete corresponding to one row of the design.

- Both the Jacquard process and the necessary loom attachment are named after their inventor. This mechanism is probably one of the most important weaving inventions as Jacquard shedding made possible the automatic production of unlimited varieties of pattern weaving.

- The term "Jacquard" is not specific or limited to any particular loom, but rather refers to the added control mechanism that automates the patterning. The process can also be used for patterned knitwear and machine-knitted textiles, such as jerseys.

- This use of replaceable punched cards to control a sequence of operations is considered an important step in the history of computing hardware.

How did the jacquard develop?

-

-

-

-

- Traditionally, figured designs were made on a drawloom. The heddles with warp ends to be pulled up were manually selected by a second operator, the draw boy, not the weaver. The work was slow and labour-intensive, and the complexity of the pattern was limited by practical factors.

- The first prototype of a Jacquard-type loom was made in the second half of the 15th century by Jean le Calabrais. He introduced a new kind of machine which was able to work the yarns faster and more precisely. Over the years, improvements to the loom were ongoing.

- An improvement of the draw loom took place in 1725, when Basile Bouchon introduced the principle of applying a perforated band of paper. A continuous roll of paper was punched by hand, in sections, each of which represented one lash or tread, and the length of the roll was determined by the number of shots in each repeat of pattern. The Jacquard machine then evolved from this approach.

- Joseph Marie Jacquard saw that a mechanism could be developed for the production of sophisticated patterns. He possibly combined mechanical elements of other inventors, but certainly innovated. His machine is credited with having fully perforated each of its four sides - a modification that enabled him to increase the figuring capacity of the machine. In his first machine, he supported the harness by knotted cords, which he elevated by a single trap board.

- The term "Jacquard loom" is somewhat inaccurate. It is the "Jacquard head" that adapts to a great many dobby looms that allow the weaving machine to then create the intricate patterns often seen in Jacquard weaving.

- Jacquard-driven looms, although relatively common in the textile industry, are not as ubiquitous as dobby looms which are usually faster and much cheaper to operate. However, dobby looms are not capable of producing so many different weaves from one warp.

- Modern jacquard machines are controlled by computers in place of the original punched cards, and can have thousands of hooks.

- The threading of a Jacquard machine is so labor-intensive that many looms are threaded only once. Subsequent warps are then tied into the existing warp with the help of a knotting robot which ties each new thread on individually. Even for a small loom with only a few thousand warp ends the process of re-threading can take days.

- Originally the Jacquard machines were mechanical, and the fabric design was stored in a series of punched cards which were joined to form a continuous chain. The Jacquards often were small and only independently controlled a relatively few warp ends. This required a number of repeats across the loom width. Larger capacity machines, or the use of multiple machines, allowed greater control, with fewer repeats, and hence larger designs could be woven across the loom width.

-

-

-

Are mechanical jacquard machines costly to maintain?

A factory must choose looms and shedding mechanisms to suit its commercial requirements. As a rule the more warp control required the greater the expense. So it is not economical to purchase Jacquard machines if one can make do with a dobby mechanism.

As well as the capital expense, the Jacquard machines are more costly to maintain, as they are complex and require higher skilled personnel; an expensive design system is required to prepare the designs for the loom, and possibly a card-cutting machine.

Weaving is more costly since Jacquard mechanisms are more likely to produce faults than dobby or cam shedding. Also, the looms will not run as quickly and down-time will increase because it takes time to change the continuous chain of cards when a design changes.

For these reasons it is best to weave larger batches with mechanical Jacquards.

When did the electronically controlled jacquards come into existence?

The first successful electronic Jacquard was launched in 1983 at ITMA, Milan. Although the machines were initially small, modern technology has allowed Jacquard machine capacity to increase significantly, and single end warp control can extend to more than 10,000 warp ends. The advantages:

-

-

-

-

- That avoids the need for repeats and symmetrical designs and allows almost infinite versatility.

- The computer-controlled machines significantly reduce the down time associated with changing punched paper designs, thus allowing smaller batch sizes. However, electronic Jacquards are costly and may not be required in a factory weaving large batch sizes, and smaller designs. However the larger machines allowing single end warp control are very expensive, and can only be justified where great versatility is required, or very specialized design requirements need to be met.

- Jacquard weaving uses all sorts of fibers and blends of fibers, and it is used in the production of fabrics for many end uses.

- Jacquard weaving can also be used to create fabrics that have a brocade

-

-

-

How is the modern day Jacquard useful in making designs on sarees?

Even the Indian garment the saree makes use of the jacquard loom beautifully. A sari or saree is a woman's garment from the Indian subcontinent that consists of a rectangular shape and used to drape around the body. Varying from 4.5 to 8 meters (5 to 9 yards) in length and 60 to 120 centimetres (2 to 4 feet) in breadth the saree is typically wrapped around the waist, with one end draped over the shoulder while baring the midriff.

Expensive saris have elaborate geometric, floral, or figurative ornaments or brocades created on the loom, as part of the fabric. Sometimes threads of different colours are woven into the base fabric in patterns; an ornamented border, an elaborate pallu, and often, small repeated accents in the cloth itself. These accents are called buttis.

For fancy saris, these patterns could be woven with gold or silver thread, which is called zari work. For producing ornamented decorative designs with zari in border, body and pallu, it is essential to use special shedding device along with healds shedding in handloom to operate the vertical warp series of cloth in desired figurative order and introduce horizontal weft pick in the cloth.

Gadwal (Andhra Pradesh), YN Hosakote and Molakalmuru (Karnataka) are also famous for traditional and contemporary silk sarees. During the past two decades, all the said handloom clusters have been adopting modernized methods, machines and mechanism for weaving fashionable silk sarees by dispensing the old techniques used in preparatory, weaving and designing processes.

What is gained by the saree weavers in using electronic jacquard?

Use of indigenous electronic jacquard in place of mechanical jacquard for weaving traditional and also contemporary fashionable handloom silk sarees is a revolution seen now-a-days in all the above silk saree weaving clusters of India. The value added niche products, produced easily by using handloom electronic jacquard could be sold at high cost, which in turn fetches considerable earnings to the skilled weavers who operate the modernized handloom.

Looking to the demand, the mechanical jacquard manufacturers in India traced the concept of electronic jacquard machine and have started manufacturing indigenous electronic jacquards by producing all the accessories required for assembling. They have also modified the drive of electronic jacquard from continuous to intermittent using servo motor which paved way to use the electronic jacquard for handloom industry. Today silk saree producing centers in India have gradually started using electronic jacquard of capacity ranging from 480 to 5376 ends control.

How is the design created?

Weaving pallu, border and body in solid colour is one of the features of traditional sarees of India. Out of 5.5 meters length of saree, the first ½ to ¾ meter of ‘pallau’ is in solid colour for its full width – say blue. The border colour is also same as the colour of pallau, that is blue. The centre body part, leaving the pallu and border is in another solid colour contrast to that of blue – say orange. The purpose of having solid colour for the pallu, border and body is to have it as back ground over which the ornamentations of designs could be shown prominently in extra warp and extra weft principles

What is the extra warp & extra weft ?

Different design layout of silk saree is brought by the combination of extra warp and extra weft weaving principle. The borders of silk saree on both the sides are ornamented mostly with gold zari in extra warp woven using silk ground warp and zari extra warp combined with silk weft. Ground warp is controlled by healds and extra warp ends by jacquard. The figured motif used for extra warp ornamentation is of vertical running nature.

What do you have to say about the borders?

The vertical border motif has main border in the centre and supporting borders at the left and right side of main border. All the elements in the repeat of vertical border design get completed both at left and right side and have proper joining at the top and bottom side.

The horizontal border motif has main border in the centre and supporting borders at the top and bottom of main border. All the elements in the repeat of horizontal border design get completed both at the top and bottom side and have proper joining at the left and right side. The horizontal border design is mostly same as vertical border design, turned to 900. The middle of pallu portion is woven with all over running figured design using gold zari in extra weft principle.

What about the pallu and the body?

In the centre portion of saree, the pallu is ornamented with extra weft, woven using silk ground weft and zari extra weft combined with silk warp controlled by jacquard. The beginning and end of pallu is normally woven with horizontally running gold zari extra weft figured designs.

To make the saree very exclusive and elegant, the complete body portion is also woven with all over running figured design using gold zari in extra weft principle.

All the elements in the repeat of all over design have proper joining at left and right side and also have proper joining at the top and bottom side.

The body portion of saree, sometimes is woven as simple figured cloth using silk warp and silk weft without any extra weft. In this case the colour of weft used is different to that of warp colour and the design is made to have more plain ground with less amount of figure formed by floating silk warp or weft.

What do you have to say about the Buttis?

In most of the silk saree layouts, along with the above said vertical, horizontal and allover figured ornamentation, buttis woven with gold zari in extra weft principle are also combined. Buttis are placed in border, pallu and body portions of the saree as per the required ornamentation. According to the place where the butti is woven, it is called as Border butti, Pallu butti, Body butti and Corner butti. The butti is called as ‘Corner butti’ when it is placed in the junction place of border, pallu and body. As seen above, when more attractiveness and ornamentation is required, all the figured design used in border, pallu and border must be more elaborative and gigantic in size. The introduction of electronic jacquard in handloom with huge capacity of hooks has made it possible to achieve this goal easily.

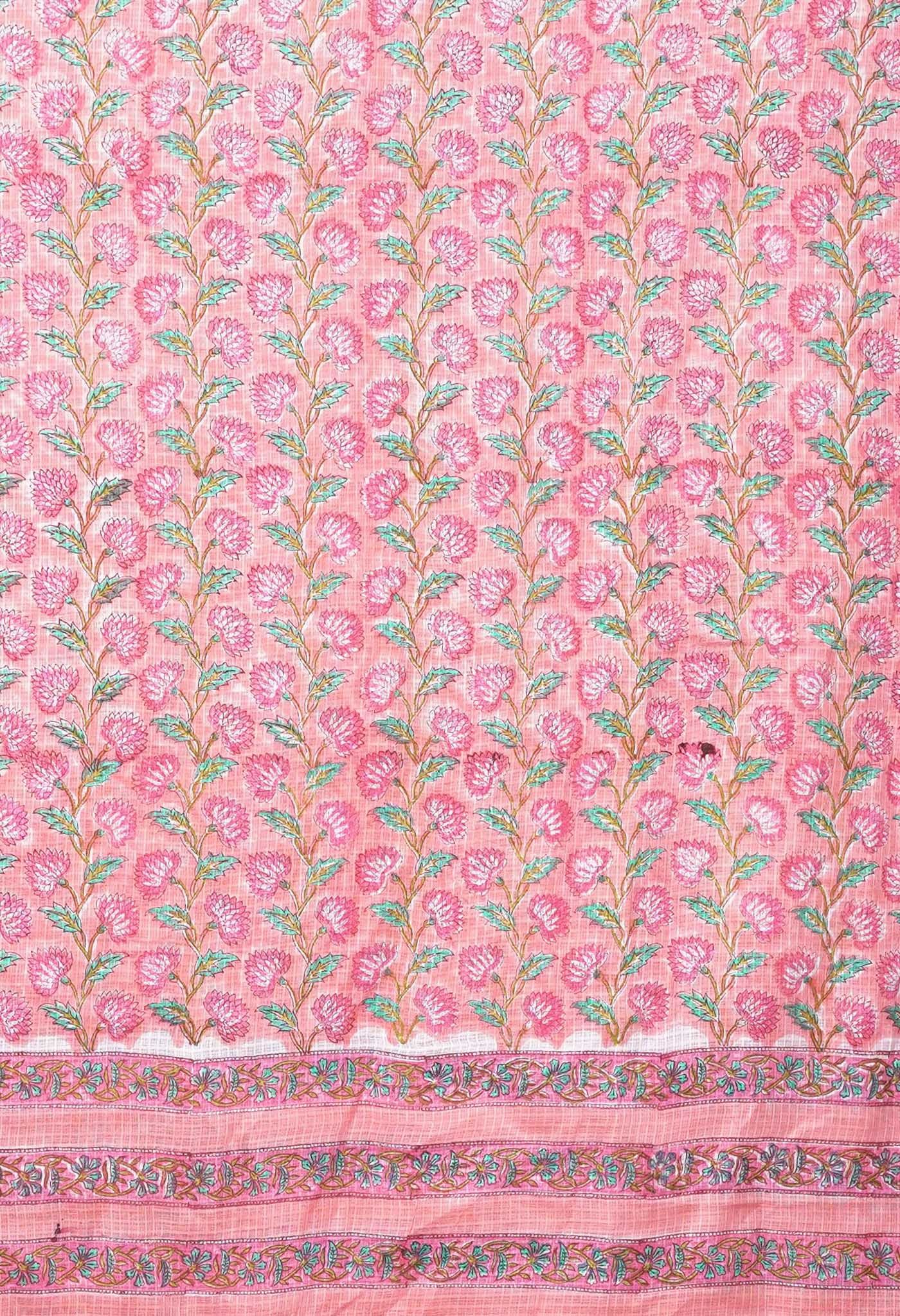

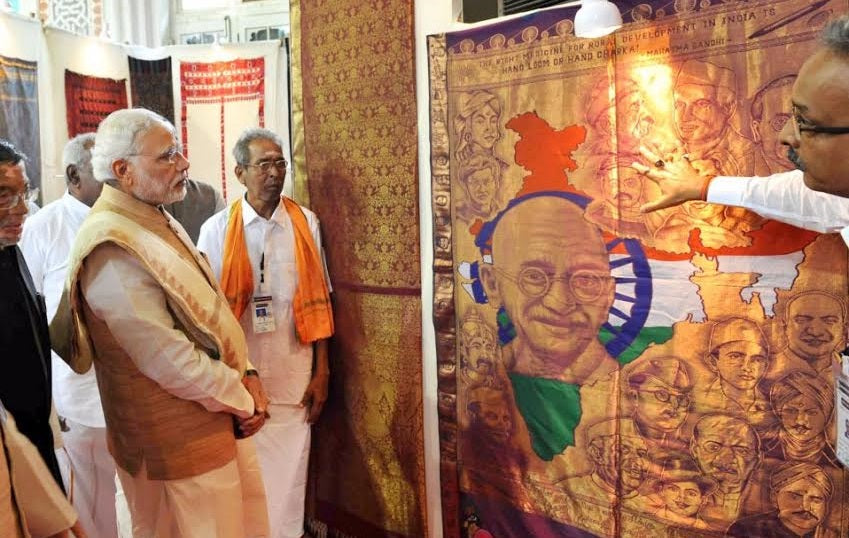

Unnati Silks and Jacquard designs on sarees

Unnati Silks and Jacquard designs on sarees

Unnati Silks has been associated with Handlooms since 1980 and acknowledges the beauty created by Jacquards. In some of its saree varieties you see extraordinary jacquard designs such as in the Mysore cotton sarees especially. Here are some examples for you.