A Tale of Silk

The mere mention of silk and most women have their ears perked up for what is to follow. The queen of fabrics, the most beautiful of textiles, Silk has undisputedly been acknowledged as the costliest of fibres, that comes from the cocoons of the silkworm, and is soft, smooth and extremely desirable as fabrics, to women all over the world. It also occupies a place of pride in traditional rituals and festivals besides the usual desirability as attractive and eye-catching wear.

China is one of the major producers of the silk yarn in the world, the others being India, Uzbekistan, Brazil, Japan, Republic of Korea, Thailand, Vietnam, DPR Korea, Iran, etc.

The salient features of silk

- Silk with its inherent tensile strength is considered the strongest of fibre materials, i.e. it can be pulled quite a lot without breaking. However this does not mean that silk will stand up to heavy wear. In fact some fibres have better abrasion resistance compared to that of silk.

- Silk has a wide range in terms of appearance from a raw unpolished surface to a highly shiny glistening fabric, based on the level to which it has been processed. As the refinement progresses the density of a single strand of yarn reduces.

- Because of its sensitive nature, prolonged exposure to sun or mild heat would discolour a silky fabric, alkaline, acidic or oily substances would leave a stain. This is why those who know are careful to avoid getting into situations which could leave a permanent telling mark on the silky fabic.

- The shimmering appearance of silk is due to the triangular prism-like structure of the silk fibre which allows silk cloth to refract incoming light at different angles, thus producing different colors.

The Indian silk trail

India is the second largest producer of silk in the world after China. About 97% of the raw silk comes from five Indian states, namely, Andhra Pradesh, Karnataka, Jammu and Kashmir, Tamil Nadu and West Bengal.

In Karnataka, Bangalore, Ramanagara and are the known silk hubs. In Tamil Nadu, mulberry cultivation is concentrated in Coimbatore, Erode, Tiruppur, Salem and Dharmapuri districts. Banaras in the north, and Murshidabad in the east are well recognized locations for the silk making industry.

In the north eastern state of Assam, three different types of silk are produced. They are collectively called Assam silk: Muga, Eri and Pat. Muga, the golden silk, and Eri are produced by silkworms that are native only to Assam. Mysore

India is also the largest consumer of silk in the world. The tradition of wearing silk sarees for marriages and other auspicious ceremonies exists in many parts of India. Silk is considered to be a symbol of royalty, and, historically, silk was used primarily by the upper classes.

The process of making silk

The process of making silk

The production of silk filaments for making silk cloth is through the production of cocoons. The species Bombyx Mori is usually cultivated and raised under controlled conditions of environment and nutrition. Silk is produced by several insects, but generally only the silk of moth caterpillars has been used for textile manufacturing. There has been some research into other types of silk, which differ at the molecular level.

The life cycle of silk worm is in four stages - the egg, the silk worm, the pupa and the moth. The silk worm which feeds on mulberry leaves forms a covering around it by secreting a protein like substance through its head. This stage is called cocoon, the desirable stage for the silk producers.

Next the cocoons are collected and the filature or silk strands are unwound from them. Strands unwound thus are collected as skeins. The entire process involves four steps.

- The cocoons are sorted according to the color, size, shape and texture as these affect the final quality of the silk. Cocoons may range from white and yellow to grayish.

- Silk filament is a double strand of fibroin, which is held together by a gummy substance called sericin or silk gum. After the cocoon has been sorted, they are put through a series of hot and cold immersions, as the sericin must be softened to permit the unwinding of the filament as one continuous thread.

- Reeling is the process of unwinding the silk filaments from the cocoon and combining them together to make a thread of raw silk. As the filament of the cocoon is too fine for commercial use, three to ten strands are usually reeled at a time to produce the desired diameter of raw silk which is known as "reeled silk". The useable length of reeled filament is 300 to 600 m.

- The silk filament is reeled into skeins, which are packed in small bundles called books, weighting 2 to 4.5 kg. These books are put into bales weighing about 60 kg. In this form raw silk is shipped to silk mills all ove r the world.

Distinguishing Silk from the ‘Burn Test’

Silk is made out from burning a sample piece and finding a powdery residue. When the flame is removed, it does not burn further but extinguishes. Sometimes wool is confused with silk. Wool burns and gives out the smell of burning hair, whereas silk gives a very disagreeable smell.

Varieties of Natural Silk

There are numerous species of silk moths, scientists have identified about 70 which have economic value. Commercially only 4 of them are useful for the manufacture of fabric yarn. Mulberry, Tasar or Tussar, Muga and Eri are the four types. Mulberry is identified as the domesticated variety, the other three being known as wild silk since they grow on trees in the forest in natural conditions.

The types in Mulberry Silk

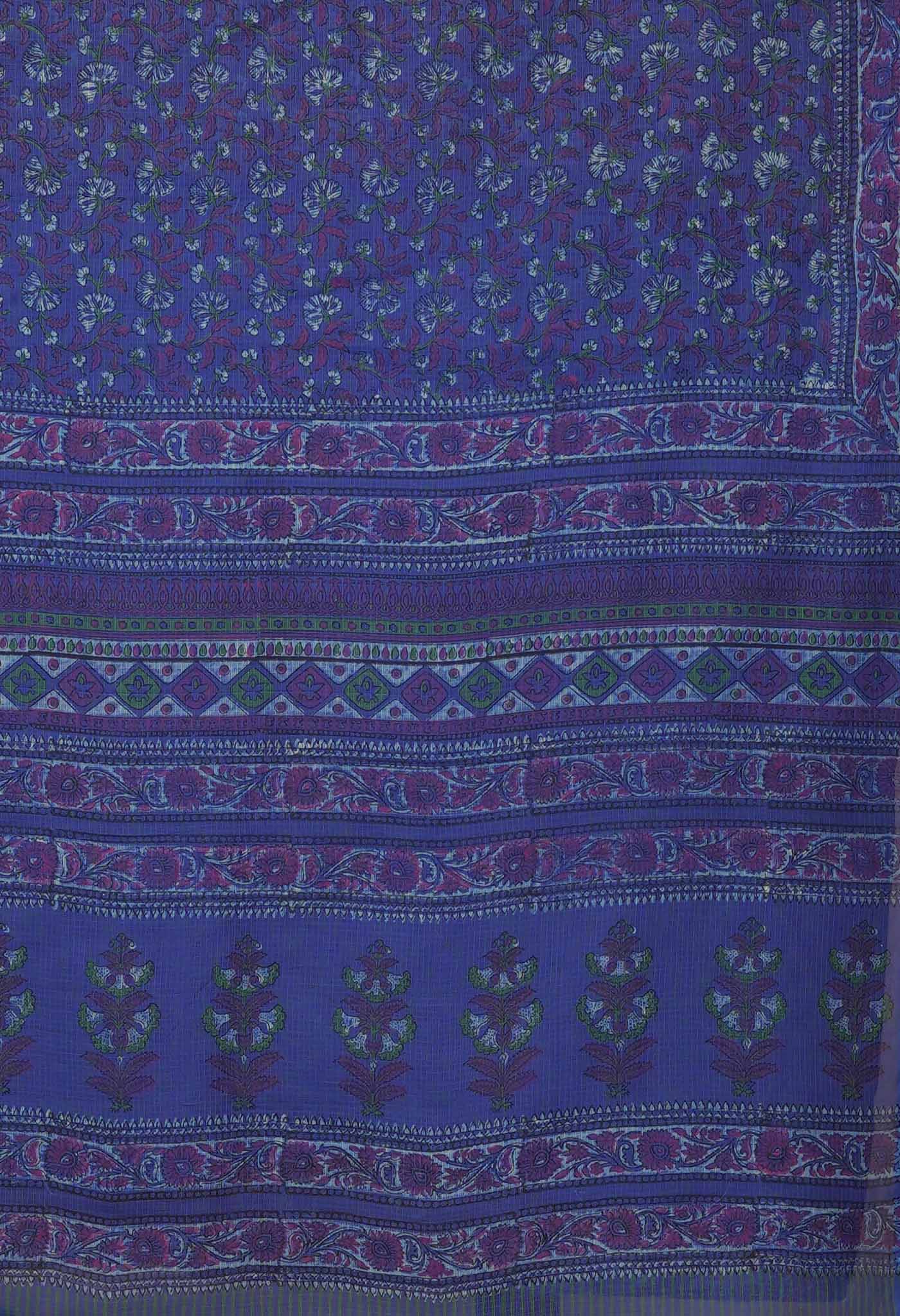

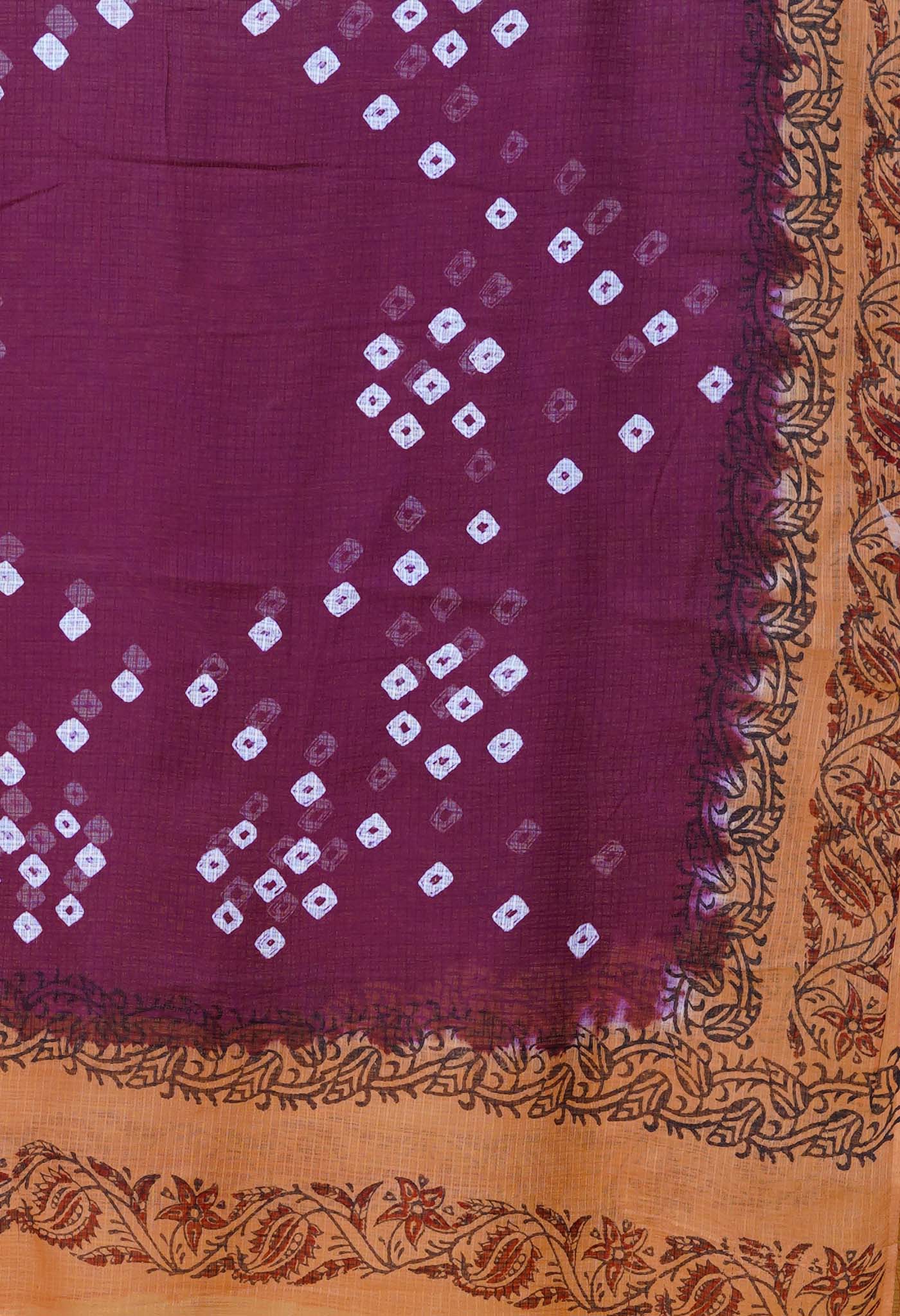

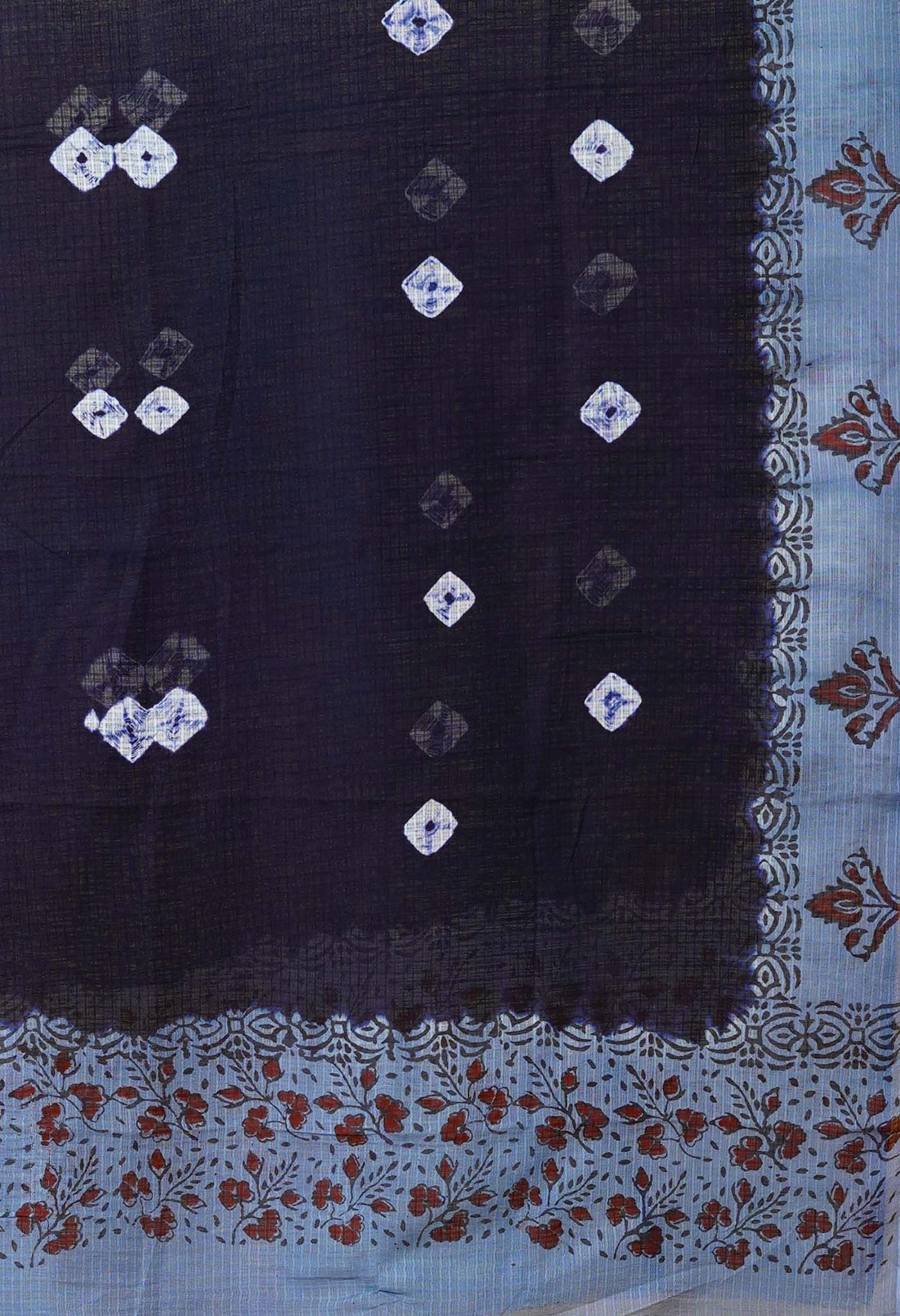

Plain silk – a range containing thin silk to deluxe quality, the fabrics range from 20 gm to 70 gm. Plain silk is mostly used by exporters for making ladies blouses, fashion garments, made-ups and scarves.

Dupion silk – the fabric is made out of twisted filature warp and dupion weft. There is generally an insistence of stripes and checks. Mainly used for dress material and cushion covers and furnishings.

Charkha Silk – Using filature in warp and charkha in weft, it is a slightly thicker fabric. Charkha refers to hand spinning i.e. charkha silk would mean Silk spun on a hand spinning machine. For most of the zari decorative sarees charka yarn is popularly used by the sari manufactures.

Chiffon Silk – Using highly twisted yarn, a thin but strong fabric is produced on power looms, which after processing and finishing attains a soft and smooth texture. Chiffons are used for varied end-uses for ladies garments and scarves/stoles.

Crepe Silk – Produced from 2-ply twisted yarn of 's' and 'z' twist and woven on power loom, crepe is used for varied uses. Crepe saris are very popular in domestic and export front.

Organza - A very thin fabric produced from highly twisted yarn. After a starchy finish the fabric gets a rough texture. Organza is used as sari material as well as for embroidered garments.

Organza - A very thin fabric produced from highly twisted yarn. After a starchy finish the fabric gets a rough texture. Organza is used as sari material as well as for embroidered garments.

Satin - Silk satins are a popular variety of fabric used for a varied end use and especially when made into dresses, satin gives an elegant Look. Banarasi Satin Saris are very popular in export and domestic markets.

Tabby Silk – A type of plain silk fabric produced in Kashmir. Tabby silk is mostly used for printed saris and scarves.

Murshidabad Silk – A popular silk fabric produced in the Murshidabad district of West Bengal. Used mainly for saris and scarves.

Matka Fabric - Using Matka yarn for both warp and weft, a thicker fabric is produced mostly for furnishing. The fabric mostly produced in Bhagalpur is a very popular export item. By using multiple yarns the texture and thickness of the fabrics can be modified according to the end use.

[/vc_column_text][vc_video link="https://www.youtube.com/watch?v=cp7MlAtNiVs&nohtml5=False"][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]

Silk has its unique position, and today’s requirement and social need call for whatever form it is available in. It has pride of place in Indian society and as long as rituals and festivals, social functions and weddings, and all those important and exclusive occasions that call for celebrations and gatherings in pomp and splendour, this traditional fabric yarn shall always reign.

[/vc_column_text][/vc_column][/vc_row]