Getting to know about Yarn, the raw material for the fabrics we wear

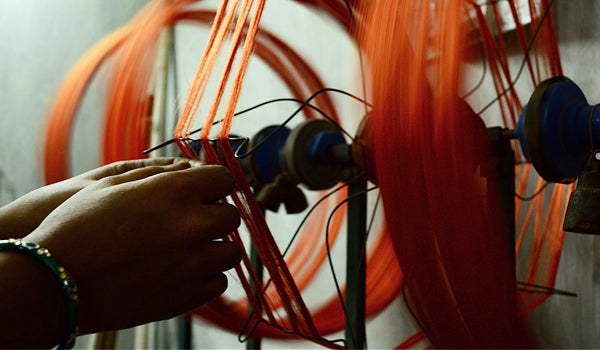

As per the English Dictionary: Yarn has been defined as ‘a continuous strand of twisted threads of natural or synthetic fibres, such as wool or nylon, used in weaving or knitting’. Fibre or Thread is defined as ‘a thin strand, cord or filament of natural or manufactured material’ OR ‘ a fine cord of a fibrous material, such as cotton or flax, made of two or more filaments twisted together and used in needlework and the weaving of cloth’.

But what is the definition of Yarn in the textile industry?

In the textile industry, ‘Yarn’ is said to be the arrangement of many short fibers or filaments in an approximate parallel state and twisted along the axis to form a slender object with a certain strength and linear density. The ‘thread’ is strands of two or more single yarns.

The Influence of Spinning on Yarn Quality

Yarn attains a stable quality only it is formed of fiber of close length and that too relatively uniform. To obtain such fibers, fibres could be taken from different production areas and batches and mixed together.

Cotton yarn is made available by using the cotton opener, the cotton mixer and the cotton cleaning machine to open, remove and mix all kinds of cotton fibres. Dust and other impurities tend to get removed by gravity and centrifugal force. While the intermittent system is often used, the yarn produced on the automatic machine is more uniform and having better strength. The production on the automatic machine is having speed and the process is continuous. This saves on manpower and also keeps the surroundings cleaner. But the quality of the yarn that is spun ultimately depends on the selection of raw materials and how thoroughly the opening, cleaning and blending process is done.

There arises a question about Yarn quality. Why is it important to analyse it?

There are two important processes in Textile – Spinning and Weaving. While the yarn forms the secondary raw material of organic fabric and knitted fabric, the finished yarn takes the form of suede thread, sewing thread and embroidered thread. The yarn structure bears a direct influence on both the internal quality of the textile as well as the appearance. So when making comparisons of quality between different textiles, it is necessary to make a comprehensive study and analysis of the type, the shrinkage factor, the fineness, twist direction etc.

Yarn fineness – It refers to the thickness degree of the yarn. In practice it is not very feasible to measure the diameter and the size of the cut surface of the yarn. So a more practical method that is adopted is the yarn count or yarn density that then leads to obtain the yarn thickness.

Yarn density - It is the mass or weight of the raw material per unit length.

What does Yarn density help with?

Yarn density plays a great role in determining how the finished product shall turn out. What and how does it do that?

The Yarn Density influences the appearance, the handle (the quality, as of textiles perceived by touching or feeling), weight and the mechanical properties of the end product or fabric. So before the yarn is spun, the yarn density is selected for which it shall be spun. Outerwear fabrics in the cold weather are to be heavy, wear-resistant, insulated and made of medium-Tex or high-Tex yarns. Whereas during the hot season, the fabric has to be lightweight, breathable and absorbent, that is got through low-Tex yarn.

Twist and the direction of twist

In the making of the yarn, it acquires some physical and mechanical properties such as elasticity, strength, elongation, luster, handle etc. In the process the structure of the yarn changes slightly with a relative displacement of its cross section so that the original parallel fibers are tilted to the central axis of the yarn.

Twisting is very much necessary for short fibers to form yarns. Twisting tends to change the yarn density, the yarn strength and the yarn gloss, thus affecting the fabric structure and properties.

Single Yarn Strength

Also known as Yarn fastness, it is an important indicator of the Yarn quality. A minimum strength of yarn is needed to ensure normal operation in the knitting process. Yarn strength is measured by a single yarn strength tester. There are two indices of the measure - The Absolute Strength and the Relative Strength.

Absolute Strength - refers to the strength the yarn needs that when it is stretched directly to break by an external force, also known as breaking strength, expressed in CN/tex.

Relative Strength - Fibers (and particularly organic fibers) are commonly porous or hollow, and threads and strands are made from bundles of fibers. This makes it very hard to accurately measure the cross-sectional area of a small thread, and therefore to compute the absolute “engineering strain” or strength of a fabric. One way to get around this problem is to measure the force to break the fibers, and then to divide by the mass (weight) of a unit length of fiber. This gives a useful measure of the “relative strength” for a given mass of material.

This is also known as the Breaking Strength /Mass of the material. E.g. If the mass/unit length of a sample of dry cotton is 0.048g/ft. and the sample breaks with a force of 10 lbs. applied, the Relative strength of Dry Cotton works out to 208 lbs. /g.ft.

Appearance Quality of the Yarn

In order to determine the appearance quality of yarns made of cotton or man-made fibers, or their blends they are wound on a blackboard. The yarn samples are then observed according to the prescribed requirements by a visual method. The following are observed: the slub, thin place, defects, systematic unevenness and NEP of the yarn.

The Significance of Yarn Quality Testing

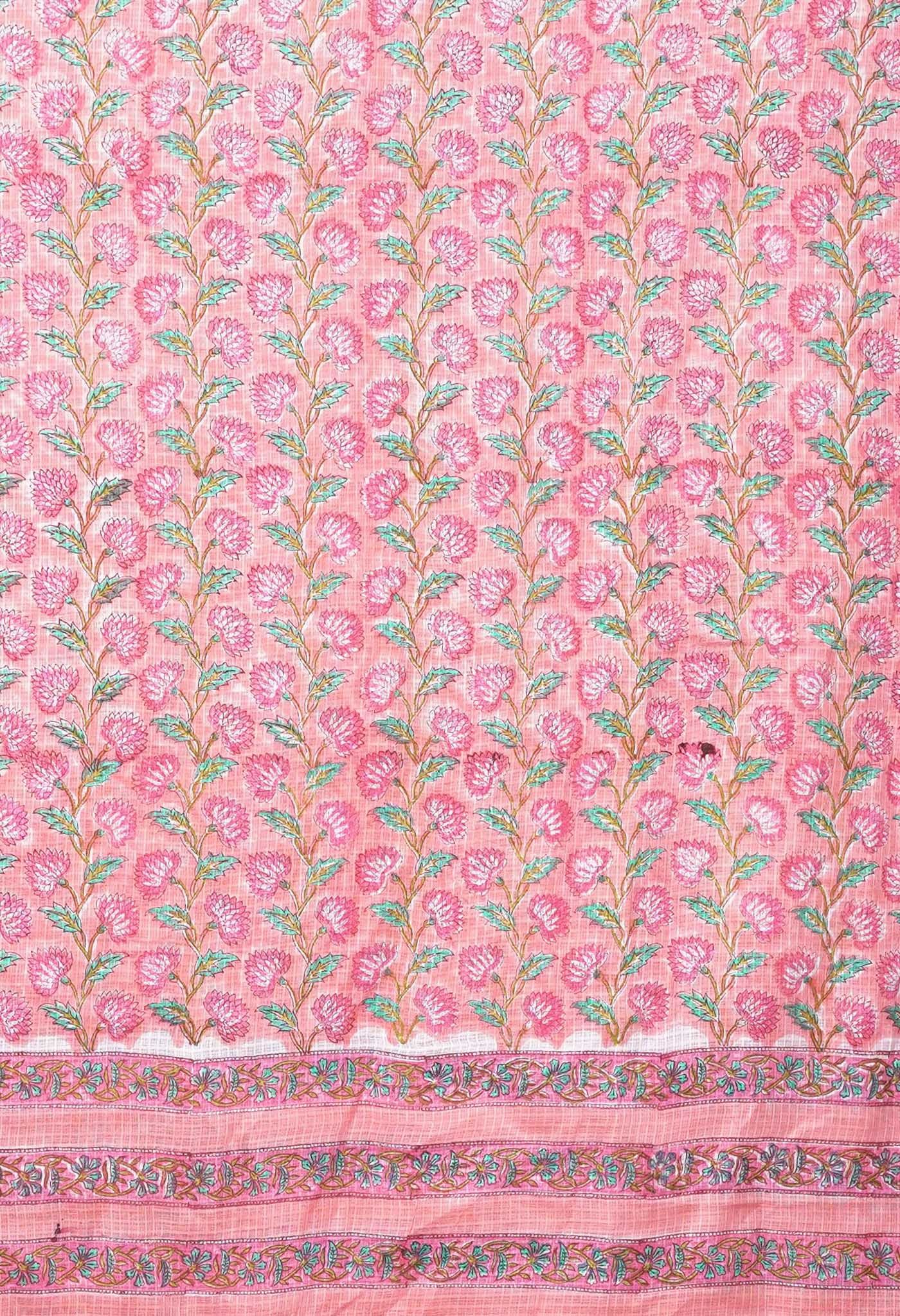

Yarns are the raw materials for weaving, fabrics with different weaving tightness, different fabric surface representation, and different printing and dyeing requirements have different demands on yarn structure. Generally speaking, there is no absolute good or bad yarn. It is suitable yarn woven on suitable cloth that achieves the best use, neither aiming to create a surplus of quality, but sufficiently satisfying to meet the basic needs of the customer for the goods.

A method to distinguish yarns of different thicknesses through numbering

Now that the facts about the making of Yarn have been briefly understood, one can proceed to learn how yarns of different thicknesses may be distinguished and partly for the important and essential function of facilitating calculations when the weight has to be taken into account in the process of manufacture.

This has been achieved through the now widely used methodology of Yarn Count.

The Yarn Count

In all the different branches of the textile industry, it has been found necessary to adopt some method of numbering the different sizes of yarn; this invariable custom is practiced partly in order that yarns of different thicknesses may be distinguished from each other.

Yarn count is an important index to distinguish different yarns. Yarn count is the degree of yarn thickness, which can be expressed by means of S, D, N, Tex, Dtex and so on. S and D are more commonly used, while specific fabrics use specific specifications, for example, the Tex. is commonly used in scientific literature.

Yarn Count Unit

S is the British count. It refers to that how many 840 yards of the yarn’s length, which is what the number of yarns counts with a pound yarn under the public moisture regain. The thicker the yarn, the smaller the S value of the yarn, for example, the 40S yarn is thinner than the 20S yarn.

D is the abbreviation of Denier, the expression of the fineness of the chemical fiber. It means that the weight grams of a 9000- meter long wire at a public moisture regain. The larger the D value, the thicker the yarn is, for example, 75D is thicker than 50D.

Tex, also known as “number”, referred to as special, old known as a public branch. It refers to the number of grams of the weight of a 1000 meter long yarn at a public moisture regain.

Tex, short for T. It refers to the grams weight number of a 1000 meter long yarn at a public moisture regain.

N is the metric branch. It refers to that how many one meters of the yarn’s length, which is what the number of yarns counts with one gram under the public moisture regain. For example, one gram weight yarn length is 200 meters long, the fineness of the yarn count is 200.

Dtex, it refers to the grams number of fiber bundles that has 10000 meters long.

The following are the interconversion formulas for several units:

D=5315/S, D=9000/N, Tex=D/9, 1Tex=1/10Dtex, Tex=1000/N, Dtex=10D/9, Dtex=10000/N

The Significance of Yarn Count

Although there are many different methods or systems of indicating the number, size, grist, or count of yarn concerning the relationships between its length and its weight, all these systems (yarn count system in textile) are modifications of two distinct groups:

1 That in which a given length is constant for any particular system, and the weight of this length is variable.

2 That in which the length is variable and the weight constant for any particular system.

The choice (if the length in Group I. or the weight in Group II. is quite arbitrary, and, indeed, there are many variations in both groups. For the sake of distinguishing between the two distinct groups you can adopt the following definition :

Group I. = fixed-length systems.

Group II. = fixed-weight systems.

In all the fixed-length systems the number or count of the yarn is directly proportional to the sectional area of the yarn; whereas in the fixed-weight systems the number or count of the yarn is inversely proportional to the sectional area of the yam. In other words, you can have:

Fixed-length systems: the thicker the yarn, the higher the count.

Fixed-weight systems: the thicker the yarn, the lower the count.

Interpretation of Yarn Count

The count is the standard of yarn thickness. The higher the yarn count, the finer the yarn, and the thinner the cloth, the softer and more comfortable it is. But the high count of cloth requires high quality of raw materials and high requirements for yarn mills and textile weaving mills, so the cost of cloth is high.

In the industry, the cloth is largely non-counted and is mainly expressed by the density of yarns (the density of yarns refers to the roots number of warp and weft yarns arranged in square inches, also known as warp and weft densities). Generally expressed by “Warp yarns number * Weft yarns number”. For example 110*90, it means that there are 110 warps and 90 weft yarns per square inch.

Misunderstanding of Yarn Count

Myth one: The more counts the better, the higher the counts, the thicker the cloth, the higher the density. Not necessarily, it is better for the higher count under the same density, but the lower the count, the thicker the yarn, the thicker the cloth.

Myth two: The cloth is poor with 30s and 40s. This is not the case, you know, over 95% of the big brands are 30s or 40s, it can be said that the majority of the supplies we see now are 30s or 40s.

Myth three: Excessive pursuit of high numbers and high density. At present, most of the cloth products in the market are 40s, if you listen to which business said they are 60s cotton, or even 80s, but be careful. Because the more the count, the more delicate the cloth color, and the more dense the cloth, the price will be very expensive, if the cloth with 80s washed, it is difficult to soak, because too dense.