How will you know the quality of your fabric?

Fabrics are nothing new to us. They always have been and shall remain a part of our lives. But do we know what they are made of, how they are made and how does one distinguish between a fabric of good quality from an inferior one?

Let us get our facts straight.

Fabric is a generic term used for the material made from yarn, a continuous strand of textile fibers or filaments (natural and synthetic), used to make clothes, accessories and home furnishings. It is made by various methods like weaving, knitting, knotting, chemically using gluing, bonding or melting together and mechanically tangling the fibers together (felting).

Here we get down to knowing the questions to be asked to find out whether we are buying what we had bargained for.

There are some pertinent questions that you ought to ask about fabric – they range from complex to simple – but all of them are relevant in one way or the other and will affect the appearance, strength and man y other desirable qualities that you will be looking for in your fabric.

1.What fiber is the fabric made of?

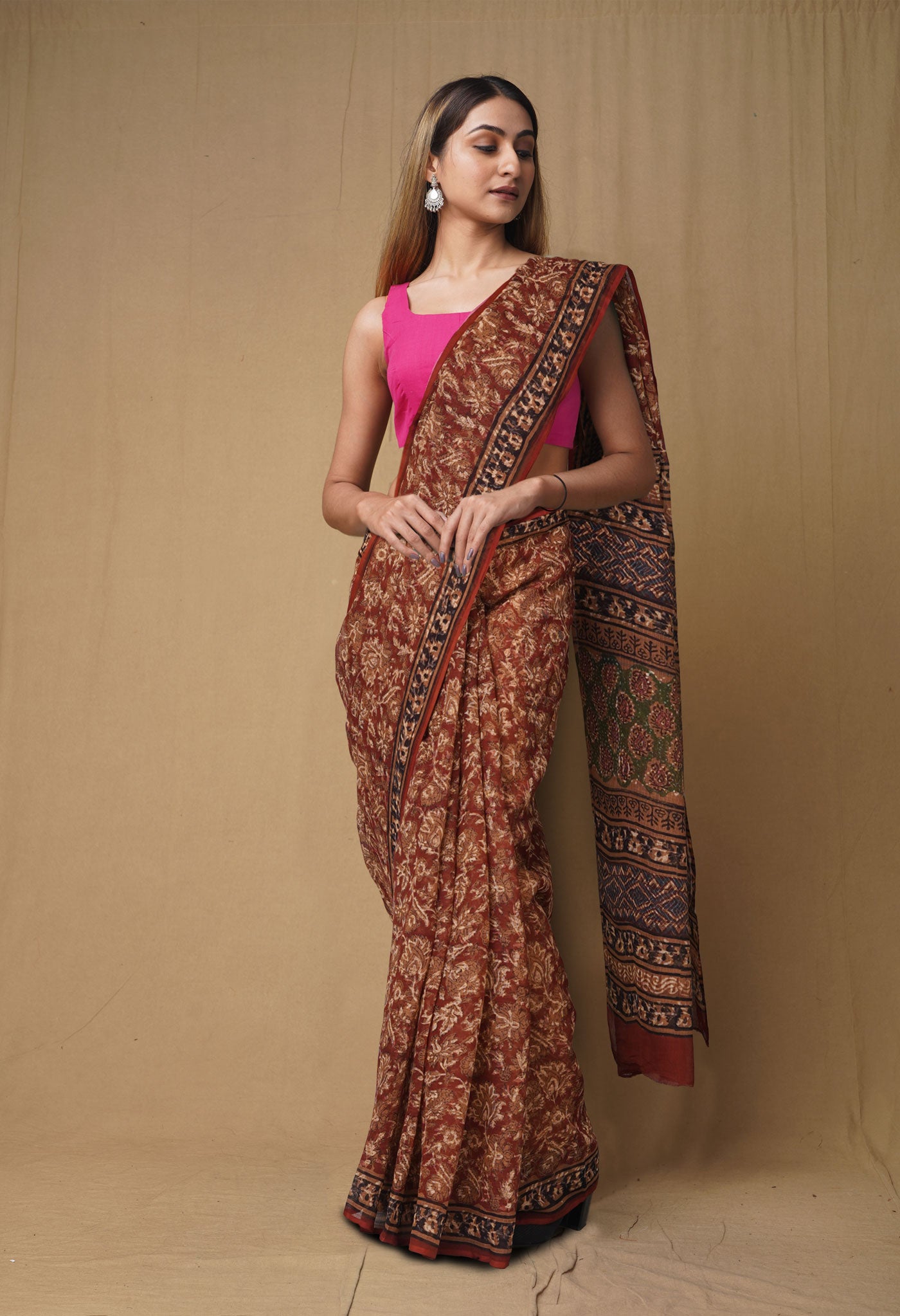

A fabric is made from yarn which is made from different kinds of fibers. It could be silk sarees, cotton sarees , wool or rayon or any other. Fibers could be made from a single particular fiber e.g. cotton, or it could be a blend e.g. Polycotton or Polycot. Fiber is the building block of your fabric.

2.What types of yarns are there in the fabric and how are they spun?

A fabric is fine or coarse depending on the type, thickness and density of its yarns. The yarn may be classified as spun yarns (made from short, staple fibers) or filament yarns (made from continuous filament fibers). Very fine cotton fabric is made of spun cotton yarn that has been combed to remove short fibers.

3.How is cotton yarn weight measured?

Cotton yarn weight is measured by the term ‘yarn number’ or yarn count. This is the number of hanks of yarn needed to make up one pound of yarn. Higher the yarn number thinner the yarn, and consequently thinner and finer the fabric.

4.How is Polyester yarn measured?

Polyester yarn is measured by the term denier. This indicates weight, in grams, of a 9000-meter length of yarn. Lower the denier finer the yarn.

5.Why is yarn twisted?

The twist of the yarns used in the fabric can change the feel of the fabric and its appearance. Well twisted yarns are stronger and will wear better than uneven, loosely twisted yarns. Twist can increase fineness, strength and the elasticity of the yarn. Most of the yarns used in woven fabric have an average twist but some fabrics like crepe are made with yarns with high twist. But a filament yarn without much twist can make the fabric appear smoother.

6.Does direction of twist matter?

The direction of the Twist in the yarn (clockwise S twist or counter clockwise Z twist) can affect how light bounces off the fabric.

7.What is the ply of the fabric?

The ply of a fabric refers to the way the yarn that makes the fabric is twisted/used. Each strand of single yarn is referred to as a ply. Single ply and 2 ply are the most commonly used terms indicating the twist of the yarn used in making the fabric. Single ply means the fiber is twisted to make a single yarn and that is used to make the fabric. 2 Ply means two yarns are spun into a single one and then that is used to make the fabric. Knowing the ply is important as it can affect the thickness and strength of the yarn and in turn the strength appearance and absorbability of the fabric.

8.What is the fabric construction method used?

According to the way fabrics are made, you can mainly classify fabrics as woven, knits and non woven. Knitted Fabrics are made by interlocking continuous thread into rows of loops by hand or specialized machines. They have a nice elasticity to them which makes these fabrics suitable for making clothes which are comfortable and form fitting.

Woven fabrics are made by interweaving yarn with weft yarn doing over and under the warp yarn. Hand weaving is not as prevalent as machine weaving today.

The other category non woven fabrics are made by applying heat, moisture, and pressure to fibers. All have their own advantages and disadvantages.

9.What is the fabric weave?

This is important in knowing the drape and feel of the fabric and the appearance of the fabric. Finely woven fabric will have a nice drape and a smooth feel. A fabric which will ravel at the cut edges needs extra care when sewing. If you have a tightly woven fabric it may not ravel at the edges. Knits never ravel at the edges but thin knits tend to roll which is unattractive. An excessive raveling tendency is a not a good sign.

10 What is the fabric weight?

A fabric is lightweight, medium weight, heavyweight etc. Lightweight fabrics usually have a loose weave. Heavy weight fabrics usually have a tight weave

11.What is fabric weight dependent on?

Fabric weight is dependent on the yarn used. You cannot gauge a fabrics quality by looking at its weight – it is more indicative of what you can use the fabric for. E.g. a thin cotton fabric is better suited for warm climates. Thick cotton is better suited for making a bag etc.

GSM (Grams per square meter) is the term that you use for fabric weights. You can speculate on the fabric’s thickness from its gsm. A medium quality (thickness) cotton fabric would have about 150 gsm, standard one is around 180 gsm, a higher quality would be around 200 gsm.

12.What is the thread count of the fabric?

Thread count of a fabric is the number of yarns in an inch of fabric. Higher the thread count better the quality of the fabric this is the general idea. Loosely woven fabrics are not perceived as high quality fabrics as the yarns in it may pull apart at the seams and the durability of the fabric is also low. Thread count is a very misunderstood term in terms of quality of fabric. You can learn more about thread count here.

13 What are the dyeing and printing done on the fabric?

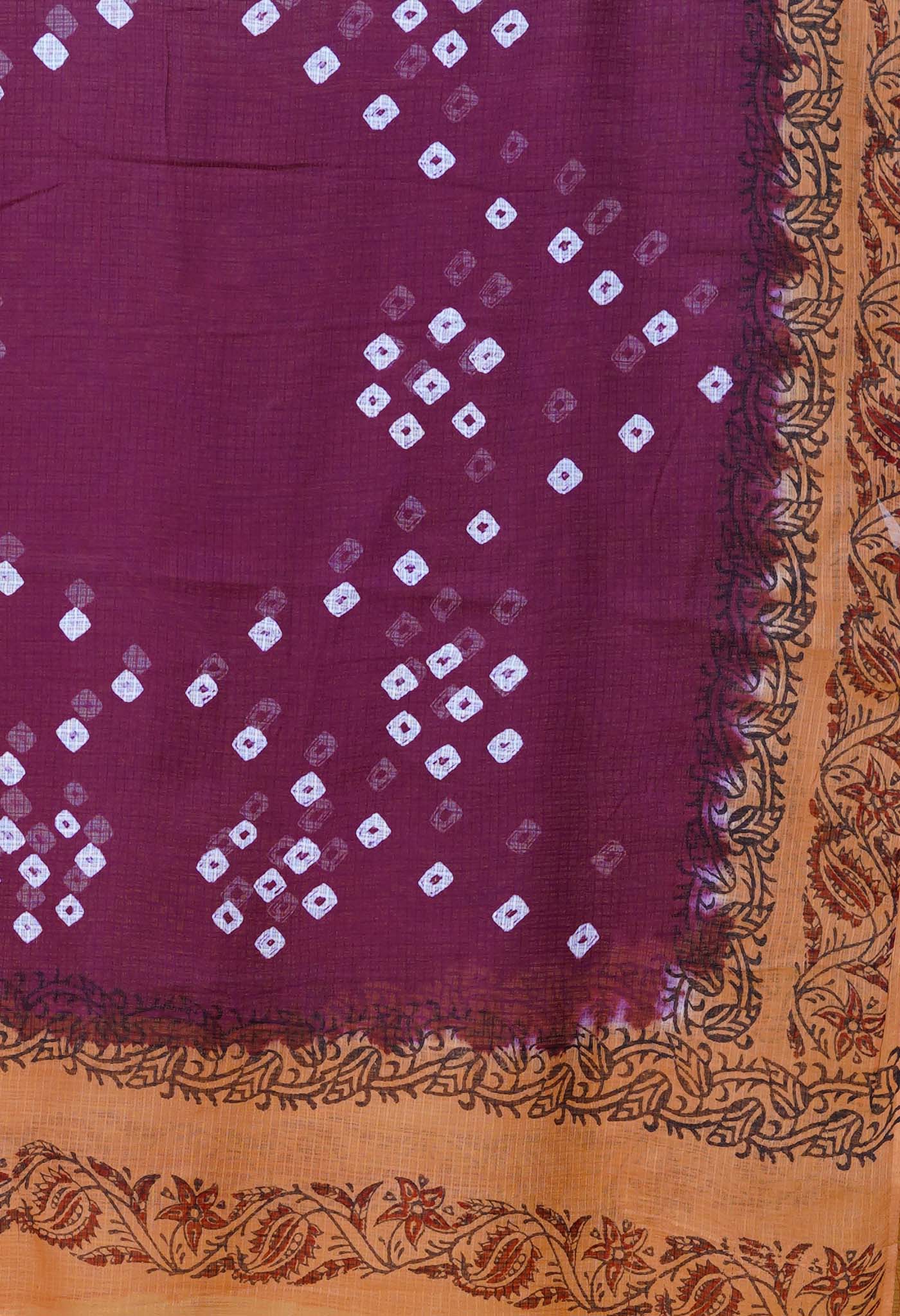

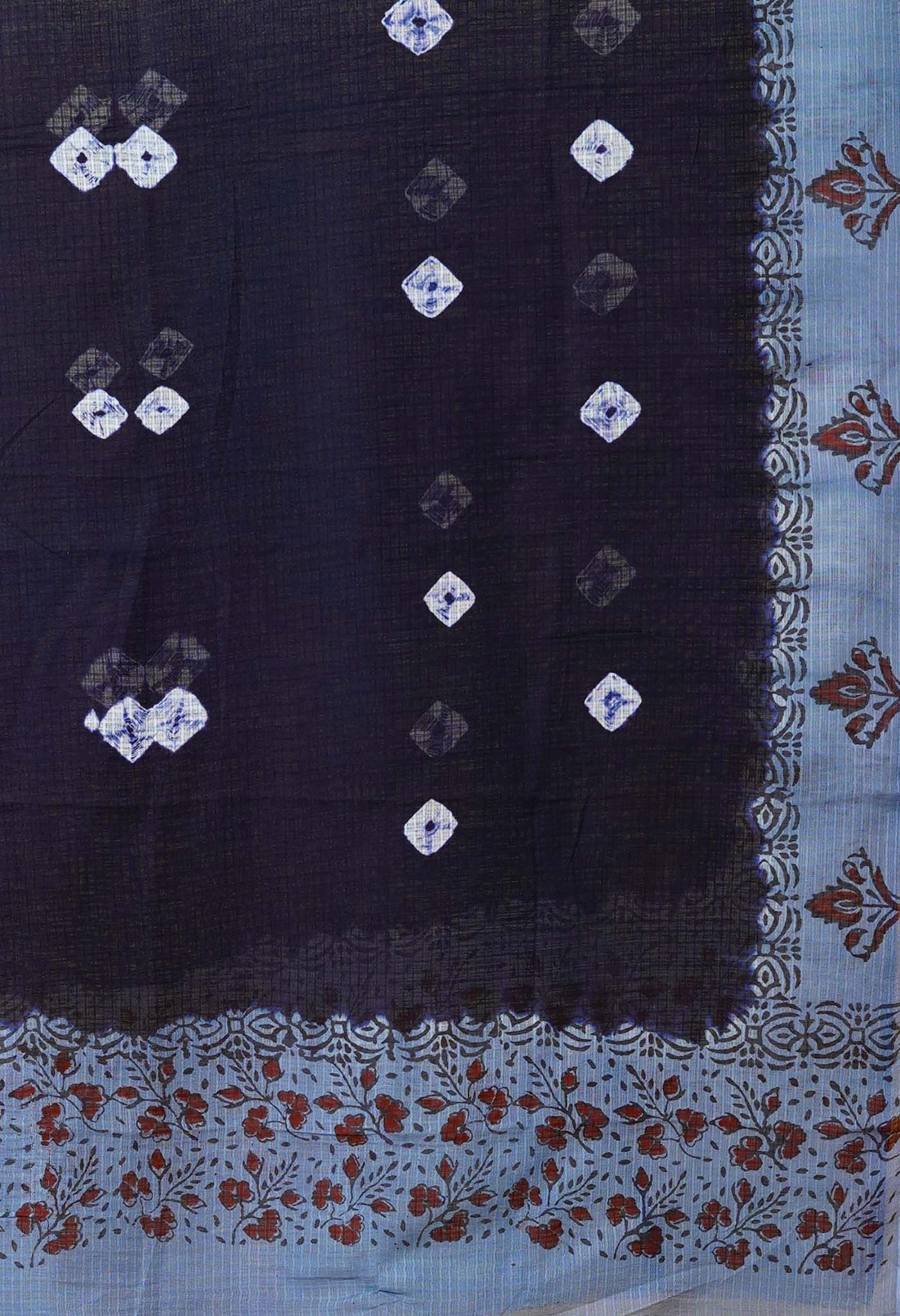

Fabric can be dyed with Chemical dyes or Natural Dyes. Natural dyeing is done using dyes sourced from plants and other natural sources like barks, leaves, roots, seeds and soil. They are used to dye silk and cotton sarees , with only alum as a mordant. The side effects of chemicals in the dye process are avoided by using natural dyes.

Designs and motifs on the fabric may be as a result of weaving with colored thread or as a result of printing done after the fabric is made. Yarn made designs are qualitatively better than printed ones. You can have a look at this post on Fabric patterns to put a name on quite a few.

14 Are the fibers of the fabric strong and resilient?

This indicates the durability of the fabric. When you use force on your fabric does it tear easily? Some fabrics will never ever. Say a polyester fabric – you have to use knife on it to tear. But some cotton fabric can tear with some ketchup spilled.

The strength of the fabric may be dependent on the type of yarns and the thickness of the warp and weft yarns.

A fabric is said to be resilient when the fabric can spring back to its original shape after being twisted, crushed, wrinkled, or distorted in any way. Wool, Polyester, Nylon are highly resilient fabrics.

15 What kind of finishes does a fabric have?

Fabric is given finishes to change its appearance and functionality. Waterproofing, Stain free, Wrinkle free, to name a few. Many of the finishes are patented by companies who invented them and have exclusive rights to use them.

16 Will the fabric absorb moisture?

This is the quality of the fabric that makes you comfortable as you wear it. Imagine wearing a dress that gives a sticky feeling when you sweat. It is the ability of fabric to take in moisture. Cotton and other natural fabrics are highly absorbent.

Wick-ability is the ability of a fiber to transport moisture away from the skin. This is an important property in active wear.

17 How good is the durability of the fabric?

This is dependent on the ability of the fiber to bend with minimal force. The fluid quality of a fabric is important in fashion designing. Usually thin and lightweight fabrics are very drapeable, but not always. Fabric cut on the bias has a good drape.

18 What is the hand of the fabric ?

This refers to the fabric texture – the way it feels as you run a hand on top of the fabric. The type of fiber used, the weave of the yarns, finishing used on the surface, all can have an effect on the type of hand your fabric has.

19 Does the fabric stretch?

A fabric is said to have elasticity and is stretchable when it is made of fibers that will stretch when you pull it. When you release it, it will go back to the same position it was in earlier. Knit fabrics stretch a lot but this also depends on the type of knit. Low quality knits will overstretch if not maintained well.

20 Does the fabric shrink ?

Minimizing shrinkage in fabrics has been a goal for textile manufacturers for years. In some fabrics like cotton the fabric weave will draw tighter after a wash. Pre-shrinking is a must for new fabrics before they are made to clothes so that the fabric would not shrink after use and look distorted. These kinds of fabrics are known as shrinkable fabrics.

Some fabrics come pre-shrunk from the bolt. They are processed so at the manufacturing unit and there is no need of preshrinking at home.

21.Does the fabric wear and tear fast or pill?

21.Does the fabric wear and tear fast or pill?

When some fabrics rub against any surface continuously, the fibers start to break at that place – some start to pill, some start to get worn with pinching fibers. There are certain fabrics which show a propensity to wear and tear and pill (a small ball of matted fibres that forms on the surface of a fabric through rubbing).

22. Is it on the grain?

22. Is it on the grain?

Sometimes the fabric will fail to line up square at the ends of the fabric or the selvages will not lie straight. This is a fabric flaw and relates to the weave of the fabric – you need a fabric which is woven on the grain so that it will fall nicely and be symmetrical as you make things with them.

The woven fabric does not show much stretch along the lengthwise grain, a little stretch along the crosswise grain and a lot along the bias grain. A straight grain line is important for the quality of your garment.

23 Would the colors of the fabric fade?

This is dependent on a lot of factors – on when the dyeing is done (at the fiber stage, the yarn stage, or the fabric stage), the type of dyes used and finally on the correct maintenance of the fabric. You can prevent color fading to a degree with good care.

24 Is it made under sustainable conditions?

Finally, can you wear garments made out of your favorite fabric without any blot on your conscience? Sustainability is a buzz word today, for very good reasons. When our survival is being challenged by climatic conditions and natural phenomena, some of which seems preventable with some pro-active action on our part, it makes sense to buy fabric which is made ethically and sustainably.

[/vc_column_text][vc_btn title="Shop Online Authentic Pure Cotton Sarees from Unnati Silks" color="warning" align="center" link="url:https%3A%2F%2Fwww.unnatisilks.com%2Fsarees-online%2Fby-base-fabric-sarees%2Fcotton-saris.html||target:%20_blank"][/vc_column][/vc_row]