Advances in the Jacquard weaving - manual to electronic

When designs were to be made on woven cloth, they had to be incorporated after the weaving was done. This involved tremendous time and effort - more the complexity of design, more the time and effort.

In 1804 when Joseph-Marie invented the Jacquard attachment it simply got woven into the warp than being printed on the surface. Complex designs could get woven within no time simply because the jacquard attachment on the mechanical loom, simply selected and lifted warp yarns to create the pattern.

The advantage of the mechanical Jacquard over handwoven fabrics

With the introduction of the Jacquard and the use of technology it became possible for a variety of colors to be used with large or small repeat in the desired range. So as things advanced, highly detailed motifs could be woven in a comparably short time.

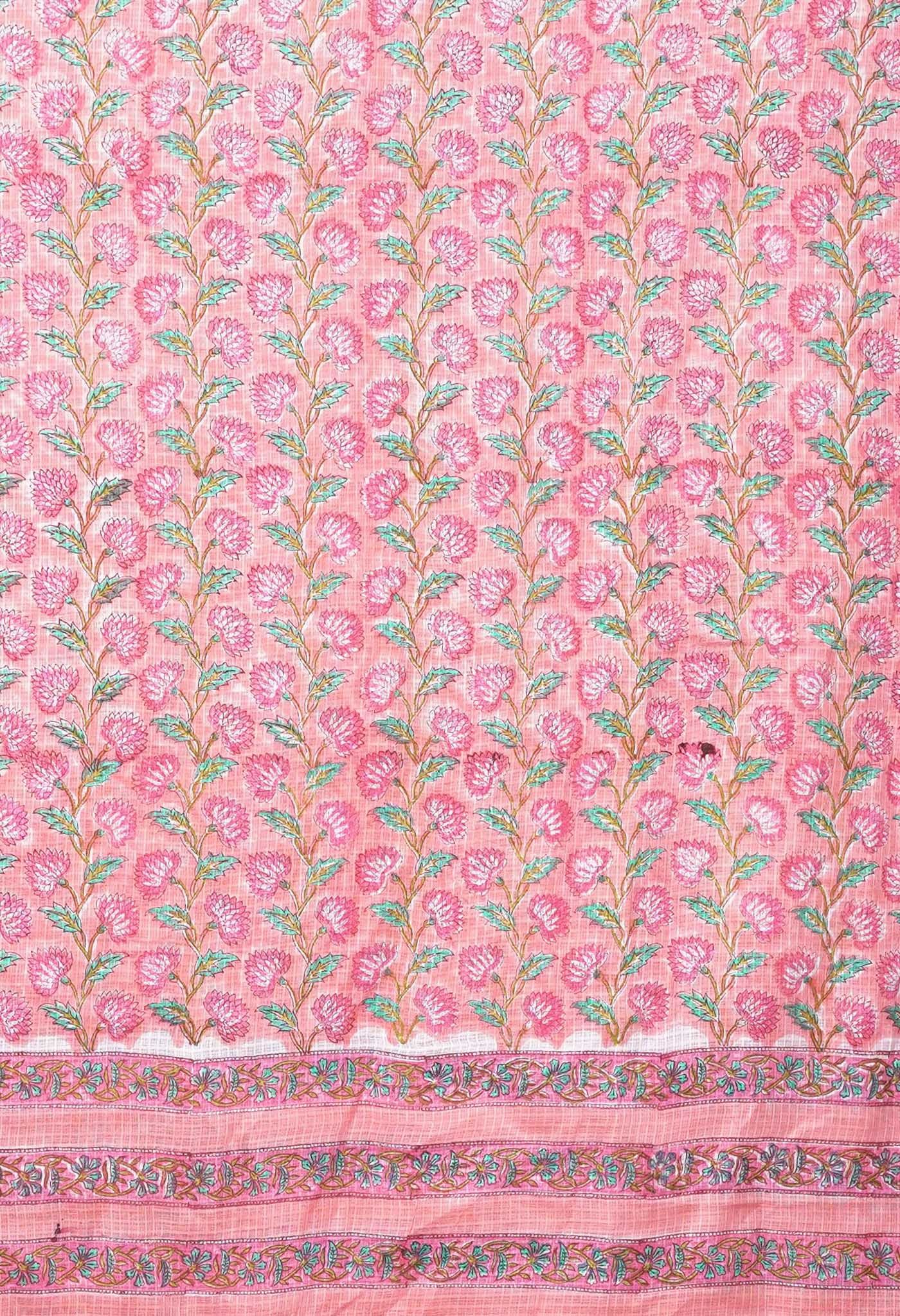

Jacquard had made it possible for literally weaving anything in one or many colors, be it geometry, flora & fauna, abstract shapes, complex figures and anything else one desired, sparing much time & effort.

Fabrics became available in a variety of compositions and weights to serve various purposes. Lightweight jacquards were picked for spring and summer apparel, whereas heavy cloths suited for colder seasons.

In fact Jacquard literally revolutionized the manner in which designs of any sort, tone-on-tone or contrast designs, with choice of patterns being unlimited: from classic stripes & polka dots to fancy botanicals, florals and even conversational themes.

Unlike prints which had to be applied to the fabric after it was woven, jacquard patterns were created together with the cloth. The beauty of the jacquard loom lay in its ability to interlace hundreds of warp threads thereby creating unique designs.

The versatility of the Jacquard

The Jacquard is a type of weave rather than a type of material. Hence it can be made with a vast range of fibers. A Jacquard fabric is all about unique patterns, that look different based on the way it is applied. Very often, if you look at the back of the cloth, you see long floats that are the threads used to produce the pattern. This indicates that the fabric has been woven with the Jacquard. Though most jacquards are woven, there are also knitted options. Jacquard knit is either a single or double knit fabric made with any yarn. Compared to single cloth, double knit has no floats on the back and is reversible.

Properties of a Jacquard fabric

Though the advantages of jacquard materials differ based upon the composition, yet they carry certain common traits. Most jacquard weave materials have floats on the back side. Over and above that they are:

Being a sturdy weave it can be woven to any desired lightness or heaviness to suit the season. E.g., cotton jacquard can be made light to suit the warm days, silk could suit lovely sarees and gowns. Wool matelasse is a nice choice for autumn and winter, while embroidered brocade would be nice for your social calendar. There are many other ways to get a whole range of Jacquard fabrics and build a nice wardrobe of beautiful, durable and unique apparel for yourself.

Replacing the mechanical Jacquard by the electronic Jacquard

The use of the indigenous electronic Jacquard in place of mechanical Jacquard is a step as revolutionary as when the Jacquard was introduced over hand woven fabrics. In India for weaving traditional and also contemporary fashionable handloom silk sarees there is a sea change seen nowadays in many silk saree weaving clusters of India.

Fashion designers & textile technologist, especially in the Southern part of India, who have understood the technicality behind the fashionable handloom silk saree woven using electronic jacquard see it as a revolution. It has indeed introduced cost-effectiveness and drastic reduction in processes.

The conventional jacquard vs Electronic Jacquard

The conventional or mechanical Jacquard machine is a device fitted to a handloom that simplifies the process of manufacturing ornamented decorative design patterns as brocade. The machine is controlled by a ‘chain of cards’; a number of punched cards laced together into a continuous sequence which are punched as per the figured design created on graph paper.

Multiple rows of holes were punched on each card, with one complete card corresponding to one horizontal row of the design in the graph and one horizontal weft pick in the cloth.

In 1983, Bonas Machine Company Ltd. launched the first successful electronic Jacquard at ITMA, Milan. Although initially the machines were small, but with the aid of modern technology, the Jacquard machine capacity was able to increase significantly with single end warp control that can extend to more than 10,000 warp ends.

What were the advantages?

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

The beneficiaries of the change from manual to electronic Jacquard

Kanjeevaram (Tamil Nadu), Banaras (Uttar Pradesh), Ashavali Brocade (Gujarat), Paithani (Maharashtra), are the well-known traditional silk sarees of India. Jamdhani cotton sarees (West Bengal), Arni (Tamil Nadu) Dharmavaram and Gadwal (Andhra Pradesh), YN Hosakote and Molakalmuru (Karnataka) are also famous for traditional and contemporary silk sarees.

All these saree producing clusters in India have since the past two decades have been adopting modernized methods, machines and mechanism for weaving both traditional and fashionable silk sarees by dispensing the old techniques used in preparatory, weaving and designing processes.

The value added niche products, produced easily by using handloom electronic jacquard could be sold at high cost, which in turn fetches considerable earnings to the skilled weavers who operate the modernized handloom.

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

What aided the revolution was:

When the mechanical Jacquard is used, let us say, for 4 sarees, then:

2500 cards are used in 960 hooks to produce a saree with new design layout. The cost would be Rs.5000 for the design, Rs.10,000 for the punched cards.

The effort would be:

The set of designs have to be changed for 4 sarees. In one month, 4 sarees are woven using this new set of cards. That means every month Rs. 15,000 has to be invested for the new set of cards when mechanical jacquard is used.

Against this if the electronic Jacquard HEJ is used:

The HEJ of 960 capacity on an average costs Rs. 2,00,000 (Rs. 200 per hook). In weaving with HEJ, for every 4 sarees, new design set is changed which requires only Rs. 5,000 as designing cost and saves Rs.10,000 invested against the punched cards for every month.

At the end of 20th month, Rs. 2,00,000 could have been saved which is equal to the cost of HEJ. That means on an average, within two years, the cost invested on HEJ could be realized and there after saves Rs. 10,000 every month.

The advantages of the electronic Jacquard over the mechanical Jacquard

There are several perceived advantages that make the HEJ (electronic Jacquard) desirable when compared to the conventional Jacquard.

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

Silk sarees have already begun to look extraordinary with the increased range of designer sarees with intricate and spruced-up displays. The market in turn has also responded with fashion designers and textile technologists gearing up to improving their offerings. Things are looking quite bright for all the stakeholders and new avenues created for job-seekers in textiles.

This shall hopefully continue till some revolutionary change was to be introduced to replace the existing.

In 1804 when Joseph-Marie invented the Jacquard attachment it simply got woven into the warp than being printed on the surface. Complex designs could get woven within no time simply because the jacquard attachment on the mechanical loom, simply selected and lifted warp yarns to create the pattern.

The advantage of the mechanical Jacquard over handwoven fabrics

With the introduction of the Jacquard and the use of technology it became possible for a variety of colors to be used with large or small repeat in the desired range. So as things advanced, highly detailed motifs could be woven in a comparably short time.

Jacquard had made it possible for literally weaving anything in one or many colors, be it geometry, flora & fauna, abstract shapes, complex figures and anything else one desired, sparing much time & effort.

Fabrics became available in a variety of compositions and weights to serve various purposes. Lightweight jacquards were picked for spring and summer apparel, whereas heavy cloths suited for colder seasons.

In fact Jacquard literally revolutionized the manner in which designs of any sort, tone-on-tone or contrast designs, with choice of patterns being unlimited: from classic stripes & polka dots to fancy botanicals, florals and even conversational themes.

Unlike prints which had to be applied to the fabric after it was woven, jacquard patterns were created together with the cloth. The beauty of the jacquard loom lay in its ability to interlace hundreds of warp threads thereby creating unique designs.

The versatility of the Jacquard

The Jacquard is a type of weave rather than a type of material. Hence it can be made with a vast range of fibers. A Jacquard fabric is all about unique patterns, that look different based on the way it is applied. Very often, if you look at the back of the cloth, you see long floats that are the threads used to produce the pattern. This indicates that the fabric has been woven with the Jacquard. Though most jacquards are woven, there are also knitted options. Jacquard knit is either a single or double knit fabric made with any yarn. Compared to single cloth, double knit has no floats on the back and is reversible.

Properties of a Jacquard fabric

Though the advantages of jacquard materials differ based upon the composition, yet they carry certain common traits. Most jacquard weave materials have floats on the back side. Over and above that they are:

- durable and stable,

- strong and resilient,

- wear- and wrinkle-resistant,

- pleasant to the touch,

- filled with decorative aesthetics.

Being a sturdy weave it can be woven to any desired lightness or heaviness to suit the season. E.g., cotton jacquard can be made light to suit the warm days, silk could suit lovely sarees and gowns. Wool matelasse is a nice choice for autumn and winter, while embroidered brocade would be nice for your social calendar. There are many other ways to get a whole range of Jacquard fabrics and build a nice wardrobe of beautiful, durable and unique apparel for yourself.

Replacing the mechanical Jacquard by the electronic Jacquard

The use of the indigenous electronic Jacquard in place of mechanical Jacquard is a step as revolutionary as when the Jacquard was introduced over hand woven fabrics. In India for weaving traditional and also contemporary fashionable handloom silk sarees there is a sea change seen nowadays in many silk saree weaving clusters of India.

Fashion designers & textile technologist, especially in the Southern part of India, who have understood the technicality behind the fashionable handloom silk saree woven using electronic jacquard see it as a revolution. It has indeed introduced cost-effectiveness and drastic reduction in processes.

The conventional jacquard vs Electronic Jacquard

The conventional or mechanical Jacquard machine is a device fitted to a handloom that simplifies the process of manufacturing ornamented decorative design patterns as brocade. The machine is controlled by a ‘chain of cards’; a number of punched cards laced together into a continuous sequence which are punched as per the figured design created on graph paper.

Multiple rows of holes were punched on each card, with one complete card corresponding to one horizontal row of the design in the graph and one horizontal weft pick in the cloth.

In 1983, Bonas Machine Company Ltd. launched the first successful electronic Jacquard at ITMA, Milan. Although initially the machines were small, but with the aid of modern technology, the Jacquard machine capacity was able to increase significantly with single end warp control that can extend to more than 10,000 warp ends.

What were the advantages?

- The need for repeats and symmetrical designs were avoided and allowed almost infinite versatility.

- Computer-controlled machines significantly reduce the down time associated with changing punched paper designs, thus allowing smaller batch sizes.

- The electronic jacquard in the handloom industry gradually become more useful in place of mechanical jacquard as well as more weaver friendly in places like India for producing elegant and elaborately figured fashionable handloom silk sarees.

- The mechanical jacquard has been converted into electronic jacquard by introducing electronic system for the selection of needles from cylinder side, keeping the other components of mechanical jacquard as it is. This makes it cost-effective since very little has to be changed but with drastically improved outcomes.

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

The beneficiaries of the change from manual to electronic Jacquard

Kanjeevaram (Tamil Nadu), Banaras (Uttar Pradesh), Ashavali Brocade (Gujarat), Paithani (Maharashtra), are the well-known traditional silk sarees of India. Jamdhani cotton sarees (West Bengal), Arni (Tamil Nadu) Dharmavaram and Gadwal (Andhra Pradesh), YN Hosakote and Molakalmuru (Karnataka) are also famous for traditional and contemporary silk sarees.

All these saree producing clusters in India have since the past two decades have been adopting modernized methods, machines and mechanism for weaving both traditional and fashionable silk sarees by dispensing the old techniques used in preparatory, weaving and designing processes.

The value added niche products, produced easily by using handloom electronic jacquard could be sold at high cost, which in turn fetches considerable earnings to the skilled weavers who operate the modernized handloom.

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

What aided the revolution was:

- Looking to the demand, mechanical jacquard manufacturers in India, traced the concept of electronic jacquard machine. Now they have started manufacturing indigenous electronic jacquards by producing all the accessories required for assembling.

- They have modified the drive of electronic jacquard from continuous to intermittent using servo motor which paved the way for use of the electronic jacquard for handloom industry.

- Today silk saree producing centers in India have gradually started using electronic jacquard of capacity ranging from 480 to 5376 ends control.

When the mechanical Jacquard is used, let us say, for 4 sarees, then:

2500 cards are used in 960 hooks to produce a saree with new design layout. The cost would be Rs.5000 for the design, Rs.10,000 for the punched cards.

The effort would be:

The set of designs have to be changed for 4 sarees. In one month, 4 sarees are woven using this new set of cards. That means every month Rs. 15,000 has to be invested for the new set of cards when mechanical jacquard is used.

Against this if the electronic Jacquard HEJ is used:

The HEJ of 960 capacity on an average costs Rs. 2,00,000 (Rs. 200 per hook). In weaving with HEJ, for every 4 sarees, new design set is changed which requires only Rs. 5,000 as designing cost and saves Rs.10,000 invested against the punched cards for every month.

At the end of 20th month, Rs. 2,00,000 could have been saved which is equal to the cost of HEJ. That means on an average, within two years, the cost invested on HEJ could be realized and there after saves Rs. 10,000 every month.

The advantages of the electronic Jacquard over the mechanical Jacquard

There are several perceived advantages that make the HEJ (electronic Jacquard) desirable when compared to the conventional Jacquard.

- The capacity of HEJ ranging from 960 to 5376 is very useful to produce elaborate designs. With this Single-repeating photo-realistic design in the full width of saree can easily be Hence it is possible to produce high-end value-added ceremonial silk sarees with advanced weaves like double / treble cloth, backed cloth and tapestry using multi colour warp and weft.

- Electronic Jacquards are also referred to as green machines, because punched cards are avoided, saving lots of trees and reducing related cost.

- Pattern change on HEJ is performed through the electronically operating software which saves considerable time and eliminates design defects.

- Loom operation becomes faster since electronic selection mechanisms and double lift operation are enabled by two sets of knives. This leads to less stress and strain put upon the silk warp because of open shed operation. Hence it is possible to weave silk warp having lesser tenacity values.

- The strain on the weaver is reduced due to the simple pressing of the pedal irrespective of capacity.

- The stress on the weaver is vastly reduced as he is free from mounting of cards and monitoring proper working of cards in the cylinder.

[penci_button link="https://www.unnatisilks.com/mysore-silk-cotton-sarees-online.html" icon="fa fa-address-book" icon_position="right" radius="2px" align="center" size="small" text_color="#fff" background="#600028" text_hover_color="#fff" hover_bgcolor="#a73e00" target="_blank"]Shop Now[/penci_button]

Silk sarees have already begun to look extraordinary with the increased range of designer sarees with intricate and spruced-up displays. The market in turn has also responded with fashion designers and textile technologists gearing up to improving their offerings. Things are looking quite bright for all the stakeholders and new avenues created for job-seekers in textiles.

This shall hopefully continue till some revolutionary change was to be introduced to replace the existing.